SCF a factory 4.0

Corporate Social Responsibility

CSR: what are the challenges for SCF?

Being a factory of the future, a factory 4.0, means implementing an ongoing corporate social responsibility (CSR) and environmental strategy.

Since 2010, SCF has been doing its utmost to implement CSR projects. This covers many aspects: procurement, management of our energy consumption, the state of our buildings and their carbon footprint, working conditions, safety and waste management.

The CSR project at SCF is led by a team of volunteers from production, procurement, sales and a project manager.

To understand the techniques involved in this complex subject, we approached ADEME, which carried out a diagnostic study. SCF is a member of Orace, an association that helps companies manage their energy consumption, as well as Atlansun.

CSR: Expanding our range of clean materials

Historically, SCF has always woven, braided and knitted linen, a beautiful yarn from French agricultural production… without doubt the yarn whose origin we are most certain of.

In line with this CSR approach, we have identified and acquired new certified yarns such as organic cotton and recycled polyester. Over time, our range of eco-responsible yarns and organic yarns has expanded, and other yarns have been added, such as recycled polyamide, recycled high-tenacity polyester, cellulose acetate yarns, recycled mercerised organic cottons, wools, etc.

Today we are able to offer our customers more than fifteen materials in natural, recycled and organic materials.

A number of projects are currently being carried out in partnership with SCF, both around French wool with the “Collectif Tricolor“ and innovative projects using recycled yarns.

Certification Oeko-Tex®

SCF is also certified Oeko-tex® Standard 100 – Class I, the strictest standard in its category. This standard applies to textile articles for the very young up to the age of 3. It is clearly the most demanding standard in its category. To go even further, SCF requires its suppliers to be up to date with their GOTS® or GRS® certification for organic or recycled yarns.

CSR: Reducing our carbon footprint

To reduce its carbon footprint, SCF moved from its old premises in Bégrolles-en-Mauges in 2015 to new, more energy-efficient buildings. The old factory is now used as a storage area and will also be dedicated to the creation of a Tiers-Lieux: a local Manufacture called “La manufacture de tressage”.

Built in 2014 and 2016, our new buildings, located 900m from the old factory, house our various manufacturing processes and offices. At the same time, we are carrying out a number of projects to achieve energy independence, including electricity production and improved insulation.

To take our CSR approach a step further, we conducted a study into the energy consumption of our machines. This enabled us to identify the machines that consume the most energy and whose motors will be changed in the coming months to continue to reduce our energy consumption.

CSR: Continuously improving working conditions for our employees

The INNOFABMOD project

With the INNOFABMOD project, financed by the Pays de la Loire Region and Europe via the ERDF* in partnership with IFTH*, SCF has equipped itself with production digitisation tools, continuous improvement of production methods via a sustainable Lean mission and experimental robots.

These new, innovative, state-of-the-art systems have increased SCF’s productivity and, above all, improved working conditions and employee safety by reducing drudgery:

- Digital information capture tools

- 5 machine tools, including PLCs: integrated into the workshops, they improve working conditions and the production process for fitting metal tips, finishing straps, surface treatments, etc., and open up new finishing possibilities for SCF.

This Factory 4.0-type project, which ended in June 2022, has enabled SCF to renew itself and enter the industry of tomorrow.

Regular customer audits

Transparent about our methods and operations, we regularly invite major fashion houses and customers to audit the working conditions of our employees, either face-to-face or by questionnaire.This expertise enables us to drive continuous improvement in working conditions and safety.

*ERDF : European Regional Development Fund

*IFTH : French Textile and Clothing Institute

CSR: Recycling our waste

Textile waste from production has always been an important issue for SCF. We therefore carried out a study of the causes, which enabled us to look at how this waste could be recycled.

Collect and donate

Several times a year, we run recycling workshops where schools, artists and associations come to our production sites to collect and recycle our surplus and production waste. In this spirit, SCF maintains partnerships with:

- ENSCI (L’École Nationale Supérieure de Création Industrielle)

- Ecole Dupérré – Paris,

- LISAA (L’Institut Supérieur des Arts Appliqués)

- Diplômes Nationaux des Métiers d’Art

- Lycée de la Mode de Cholet ….

SCF is involved in many school projects related to textile design, offering its expertise and supplying materials for study projects.

Value

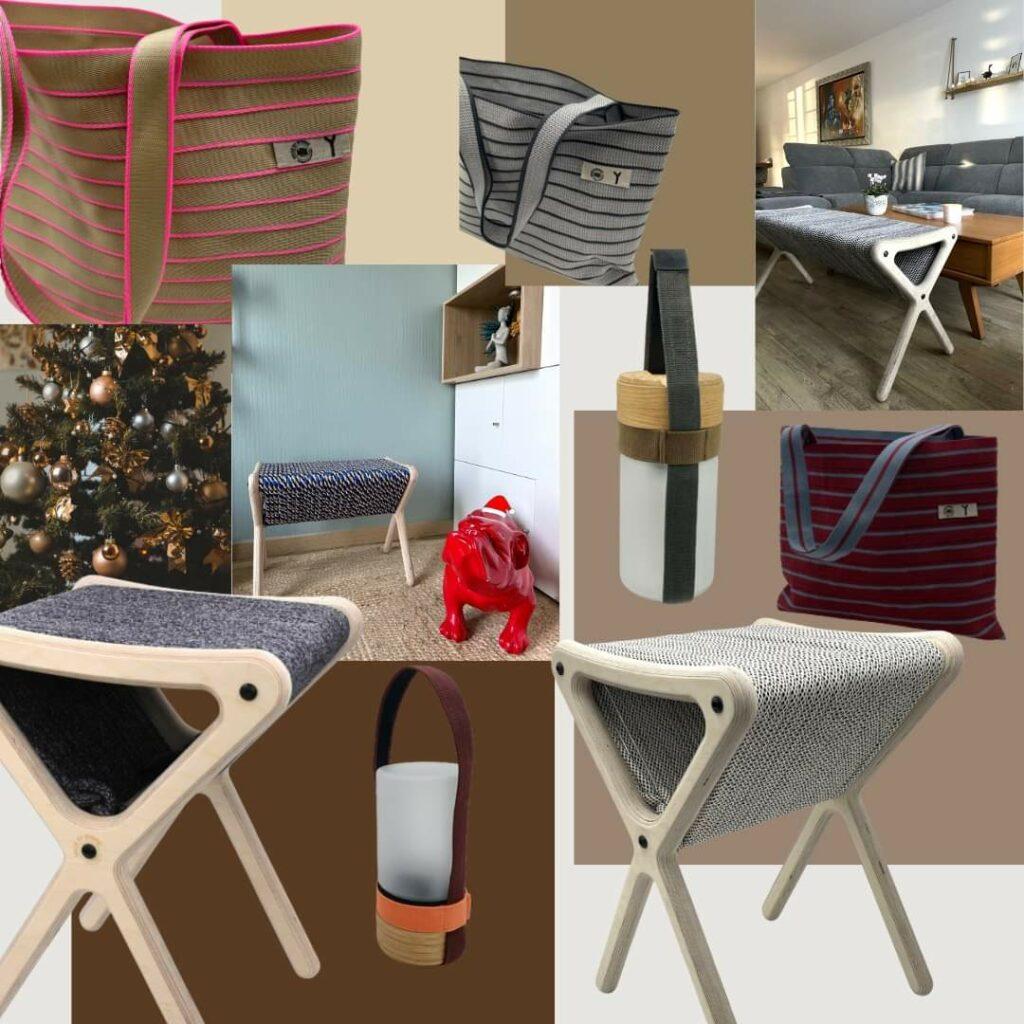

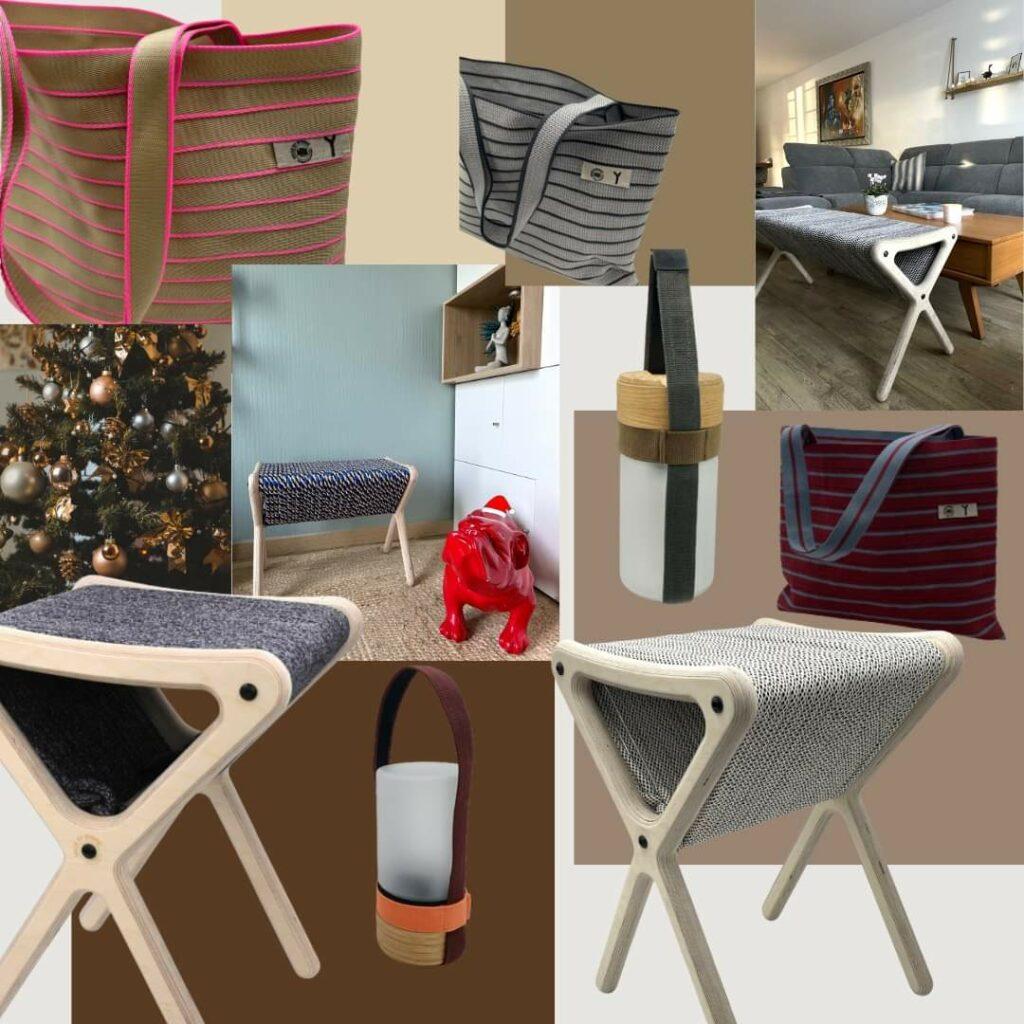

With the creation of an independent brand, initiated by 5 SCF employees, “Made by bobine” is buying up production surpluses and the end of the “collection by SCF” to develop fashion accessories and designer furniture in collaboration with designers.

All the products sold by Made by bobine are recycled.

The CABA© bag (designed by Amaury Poudray) is made from upcycled straps. These straps come from the end of production and would normally be thrown away. They are now recovered and sewn edge-to-edge by adapted companies. CABA© is available on their website www.made-by-bobine.fr.

In 2021 and 2022, another project was carried out with Made by bobine, Roger Pradier and the W110 workshop, to produce the BRIDE© lamp; here too, upcycled straps were recovered to make the handle of the lamp.

In the longer term, SCF will be participating in the local “Manufacture de tressage” currently being set up, which will be central to the waste recycling projects, in particular by offering a haberdashery made from SCF waste. The experiment has already been initiated, on a smaller scale, with our workshop-boutique in Paris, l‘Atelier de tressage.

CSR: what are the challenges for SCF?

Being a factory of the future, a factory 4.0, means implementing an ongoing corporate social responsibility (CSR) and environmental strategy.

Since 2010, SCF has been doing its utmost to implement CSR projects. This covers many aspects: procurement, management of our energy consumption, the state of our buildings and their carbon footprint, working conditions, safety and waste management.

The CSR project at SCF is led by a team of volunteers from production, procurement, sales and a project manager.

To understand the techniques involved in this complex subject, we approached ADEME, which carried out a diagnostic study. SCF is a member of Orace, an association that helps companies manage their energy consumption, as well as Atlansun.

CSR: Expanding our range of clean materials

Historically, SCF has always woven, braided and knitted linen, a beautiful yarn from French agricultural production… without doubt the yarn whose origin we are most certain of.

In line with this CSR approach, we have identified and acquired new certified yarns such as organic cotton and recycled polyester. Over time, our range of eco-responsible yarns and organic yarns has expanded, and other yarns have been added, such as recycled polyamide, recycled high-tenacity polyester, cellulose acetate yarns, recycled mercerised organic cottons, wools, etc.

Today we are able to offer our customers more than fifteen materials and counts in natural, recycled and organic materials.

A number of projects are currently being carried out in partnership with SCF, both around French wool with the “Collectif Tricolor“ and innovative projects using recycled yarns.

Certification Oeko-Tex®

SCF is also certified Oeko-tex® Standard 100 – Class I, the strictest standard in its category. This standard applies to textile articles for the very young up to the age of 3. It is clearly the most demanding standard in its category. To go even further, SCF requires its suppliers to be up to date with their GOTS® or GRS® certification for organic or recycled yarns.

CSR: Reducing our carbon footprint

To reduce its carbon footprint, SCF moved from its old premises in Bégrolles-en-Mauges in 2015 to new, more energy-efficient buildings. The old factory is now used as a storage area and will also be dedicated to the creation of a Tiers-Lieux: a local Manufacture called “La manufacture de tressage”.

Built in 2014 and 2016, our new buildings, located 900m from the old factory, house our various manufacturing processes and offices. At the same time, we are carrying out a number of projects to achieve energy independence, including electricity production and improved insulation.

To take our CSR approach a step further, we conducted a study into the energy consumption of our machines. This enabled us to identify the machines that consume the most energy and whose motors will be changed in the coming months to continue to reduce our energy consumption.

CSR: Continuously improving working conditions for our employees

The INNOFABMOD project

With the INNOFABMOD project, financed by the Pays de la Loire Region and Europe via the ERDF* in partnership with IFTH*, SCF has equipped itself with production digitisation tools, continuous improvement of production methods via a sustainable Lean mission and experimental robots.

These new, innovative, state-of-the-art systems have increased SCF’s productivity and, above all, improved working conditions and employee safety by reducing drudgery:

- Digital information capture tools

- 5 machine tools, including PLCs: integrated into the workshops, they improve working conditions and the production process for fitting metal tips, finishing straps, surface treatments, etc., and open up new finishing possibilities for SCF.

This Factory 4.0-type project, which ended in June 2022, has enabled SCF to renew itself and enter the industry of tomorrow.

Regular customer audits

Transparent about our methods and operations, we regularly invite major fashion houses and customers to audit the working conditions of our employees, either face-to-face or by questionnaire.This expertise enables us to drive continuous improvement in working conditions and safety.

*ERDF : European Regional Development Fund

*IFTH : French Textile and Clothing Institute

CSR: Recycling our waste

Textile waste from production has always been an important issue for SCF. We therefore carried out a study of the causes, which enabled us to look at how this waste could be recycled.

Collect and donate

Several times a year, we run recycling workshops where schools, artists and associations come to our production sites to collect and recycle our surplus and production waste. In this spirit, SCF maintains partnerships with

- ENSCI (L’École Nationale Supérieure de Création Industrielle)

- Ecole Dupérré – Paris,

- LISAA (L’Institut Supérieur des Arts Appliqués)

- Diplômes Nationaux des Métiers d’Art

- Lycée de la Mode de Cholet ….

SCF is involved in many school projects related to textile design, offering its expertise and supplying materials for study projects.

Value

With the creation of an independent brand, initiated by 5 SCF employees, “Made by bobine” is buying up production surpluses and the end of the “collection by SCF” to develop fashion accessories and designer furniture in collaboration with designers.

All the products sold by Made by bobine are recycled.

The CABA© bag (designed by Amaury Poudray) is made from upcycled straps. These straps come from the end of production and would normally be thrown away. They are now recovered and sewn edge-to-edge by adapted companies. CABA© is available on their website www.made-by-bobine.fr.

In 2021 and 2022, another project was carried out with Made by bobine, Roger Pradier and the W110 workshop, to produce the BRIDE© lamp; here too, upcycled straps were recovered to make the handle of the lamp.

In the longer term, SCF will be participating in the local “Manufacture de tressage” currently being set up, which will be central to the waste recycling projects, in particular by offering a haberdashery made from SCF waste. The experiment has already been initiated, on a smaller scale, with our workshop-boutique in Paris, l‘Atelier de tressage.